-

Coalescing Filter -

Filter Media -

Filtering Systems -

Filtration Equipment -

Oil Filtration -

Water Filtering Systems

Filtration Equipment

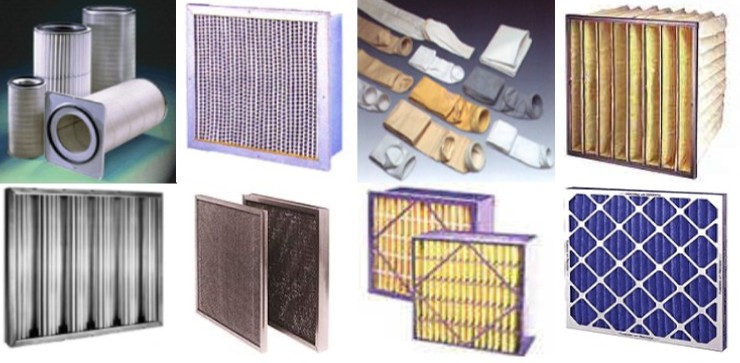

Whatever their specific configuration, filtration equipment plays a central role in an extensive range of industrial processes, and they are also vitally important in many commercial and consumer products contexts.

Throughout industry, filtration equipment is used to fulfill an extensive range of purposes. In the context of hydraulic machinery, for example, they are used to ensure the purity of hydraulic fluid, which is the actuation material in all hydraulic systems. Hydraulic filters help to ensure the safe and effective operation of hydraulic systems; this safety and effectiveness reduces the risk of product loss and employee injury.

Fuel filters are equally important examples of filtration systems; they are used to remove any contaminants from a flow of fuel before it reaches its point of combustion. This reduces the chance of contaminant-induced engine failure, which in turn improves the safety and efficiency of the engine. One of the most important filtration systems is also the most common: water filters.

Water filtering systems help to supply clean water to people and to industrial processes as well. They eliminate the spread of waterborne illness as well as improve the effectiveness of industrial processes that involve purified water as an ingredient; one such example is waterjet cutting.

Filtration equipment includes strainers, liquid cartridges, liquid housings, cartridge filters, bag filters, membranes, and ultrapure filters. Filtration equipment can filter hydraulic and quench oil, diesel fuel, machine tool coolants and numerous other industrial fluids. There are two main filtration system categories into which most filtration systems can be placed: air filters and liquid filters.

Air filters are not always used to filter air; they can be used to filter other gasses used in industrial processes as well. Liquid filters always involve the filtering of liquid, whether it involves filtering solids from a liquid or liquids from other liquids. There do exist filtering systems that separate solids from other solids, but they are not usually referred to as filters.

When selecting filtration equipment, important considerations include contaminant particle properties such as size and shape, the filtration rate of the filtration media, and filter location. Chemical compatibility of associated chemicals is also important. Other factors include the viscosity and temperature of the solution, if applicable, and the load capacity of the filter media. A majority of filtration equipment is designed for general purposes, but filter requirements may differ and require custom features.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services